Chief Scientist and a founder of Tokamak Energy, as well as a member of the executive board, Dr. Mikhail Gryaznevich has joined forces in direct collaboration with Mr. Harley O’Neill, owner of Superyacht.me, in order to be the first to take the initial steps to introduce next-generation possibilities for advance ship fusion designs.

History: Nearly 30 years ago, a group of industrial nations agreed on a project to develop a new, cleaner, and more sustainable source of energy.

ITER was set in motion at the Geneva Superpower Summit in November 1985, when the idea of a collaborative international project to develop fusion energy for peaceful purposes was proposed by General Secretary Gorbachev of the former Soviet Union to US President Reagan.

One year later, an agreement was reached: the European Union (Euratom), Japan, the Soviet Union and the USA would jointly pursue the design for a large international fusion facility, ITER. Conceptual design work began in 1988, followed by increasingly detailed engineering design phases until the final design for ITER was approved by the Members in 2001.

The People’s Republic of China and the Republic of Korea joined the Project in 2003, followed by India in 2005. Selecting a location for ITER was a lengthy procedure that was concluded in 2005, when the ITER Members unanimously agreed on the site proposed by the European Union. The ITER installation would be built near Aix-en-Provence in southern France.

Further negotiations established the ITER Agreement to detail the construction, exploitation and decommissioning phases, as well as the financing, organization and staffing of the ITER Organization.

THE ITER AGREEMENT

The ITER Agreement is signed at the Elysée Palace in Paris on 21 November 2006.In a ceremony hosted by French President Jacques Chirac and the President of the European Commission M. José Manuel Durao Barroso, the ITER Agreement was officially signed at the Elysée Palace in Paris on 21 November 2006 by Ministers from the seven ITER Members; this document established a legal international entity to be responsible for the building, operating, and decommissioning of the Project. Following the ratification of the international treaty by all Members, the ITER Organization was officially established on 24 October 2007.

The first teams arrived on-site in Saint Paul-lez-Durance, France in late 2005 after the site decision. From that moment until the start of building construction in 2010, the staff was increased to approximately 500, the nuclear licensing process was initiated; site preparatory works were carried out, and procurement agencies in each ITER Member (the Domestic Agencies) were established.

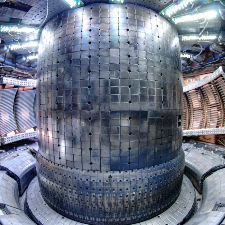

Today, thousands of people are collaborating at the ITER site in Saint Paul-lez-Durance, France, as well as in China, the European Union, India, Japan, Korea, Russia, and the United States to build the ITER Tokamak, the world’s most advanced tokamak magnetic confinement fusion experiment.

The ITER magnet system will be the largest and most integrated superconducting magnet system ever built.

Ten thousand tonnes of magnets, with a combined stored magnetic energy of 51 Gigajoules (GJ), will produce the magnetic fields that will initiate, confine, shape and control the ITER plasma. Manufactured from niobium-tin (Nb3Sn) or niobium-titanium (Nb-Ti), the magnets become superconducting when cooled with supercritical helium in the range of 4 Kelvin (-269 °C).

Superconducting magnets are able to carry higher current and produce stronger magnetic field than conventional counterparts. They also consume less power and are cheaper to operate … making superconducting magnet technology the only option for ITER’s huge magnet systems.

ITER uses high-performance, internally cooled superconductors called “cable-in-conduit conductors,” in which bundled superconducting strands—mixed with copper—are cabled together and contained in a structural steel jacket.

For the most technically challenging raw material—the niobium-tin (Nb3Sn) superconducting strands used in ITER’s toroidal field and central solenoid magnet systems—500 metric tons of strand (more than 100,000 km) were produced by nine suppliers in a procurement effort that lasted from 2008 to 2015. This large-scale industrial effort demanded a ramp-up of global production capacity from 15 metric tons/year to 100 metric tons/year, as well as the introduction of three new strand suppliers.

ASSEMBLING THE MACHINE

ASSEMBLING THE MACHINE – The ITER Tokamak is a one-of-a-kind device and one of the most complicated machines ever engineered. The ITER Organization has overall responsibility for the successful integration and assembly of components delivered to the ITER site by the seven ITER Members. This includes the assembly of the ITER Tokamak, with its estimated one million components, and the parallel installation and integration of plant systems such as radiofrequency heating, fuel cycle, cooling water, and high voltage electrical systems.

Components provided by the ITER Members as in-kind contributions will be assembled on-site in pre-determined sequences. The order and timeline for assembly events have been carefully planned in an assembly schedule that contains tens of thousands of lines for machine assembly alone. Assembly operations will require 1.5 million man-hours extending over a period of four years.

In 2016, the ITER Organization selected a Construction Management-as-Agent (CMA), the contractor. For ten years (with the option for a three-year extension) the CMA contractor will work as part of the ITER Organization construction team to plan, manage and supervise the works of the assembly phase, including the assembly of the Tokamak and parallel installation and integration of the supporting plant systems.

The actual work of the assembly phase will be carried out by ITER Organization contractors (for the assembly of the Tokamak machine and the mechanical and electrical installation of the plant systems) and Domestic Agency contractors (for some plant installation works).

The ITER Tokamak: An engineering and logistics challenge

Thirty meters in diameter and nearly as many in height, the ITER Tokamak will house a large number of sub-systems and components. The size and weight of the major components, the tiny tolerances and careful handling required for the assembly of huge and unique systems, the diversity of manufacturers, the tight schedule … all of these elements combine to make ITER an engineering and logistics challenge of enormous proportions.

“Clean areas” for machine assembly are controlled to maintain the air at a uniform temperature of 20 °C (winter) to 25 °C (summer) +/- 2 °C and relative humidity <70%. A powerful dedicated HVAC (heating, ventilation, and air conditioning) system and anti-dust coating on the floors of the assembly spaces will contribute to maintaining the required air quality. The principal assembly activities will be performed in the Tokamak Building, where the ITER device will be installed inside of a partially embedded, concrete bioshield. For the duration of assembly activities, the Tokamak Building will be operated as a “clean area” (see box) and maintained at a constant temperature to avoid dimensional changes in the largest components. Pre-assembly activities will take place in the adjacent Assembly Building.

Assembly of the ITER Tokamak will proceed in a “bottom-up” fashion. Beginning with the base section of the cryostat—the single largest and heaviest component of the ITER machine—assembly operations will continue with the lower cryostat components, the nine large, 40° sub-assembled sectors (made up of a vacuum vessel sector, surrounding thermal shields, and two toroidal field coils), and finally the components at the top of the machine.

Accurate alignment of tokamak components, particularly of the magnet system and in-vessel components, is essential to the successful operation of the machine. Assembly sequences have been planned with this in mind and will utilize sophisticated optical metrology techniques at each step of the assembly process. Dimensional control will be critical to ensuring that tolerances have adhered, and to record the “as-built” status of the machine, which will be directly compared against ITER’s Computer-Aided-Design (CAD) models in order to correct eventual deviations in alignment before they accumulate.